We have always pioneered the development of new materials

such as nylon, spandex, and silk, and have acquired

numerous patents for knitted fabrics in our 100 years of history.

Today, the company offers a wide range of products

including not only innerwear but also set-up suits for high-end brands,

uniforms for professional athletes, and other materials.

Our goal is to become a comprehensive and eco-friendly textile manufacturer

covering from raschel fabrics to tricot fabrics and circular knitted fabrics.

Bespoke Fabrics Archive

Bespoke Fabrics Archive

The Case of Raschel Tricot

The Case of Raschel Tricot

01.Planning and Development

An extremely important task to realize plans and ideas from apparel manufacturers into the form of fabrics. Especially in recent years, comprehensive know-how for materials and raw materials is required to meet the demand for high performance and high quality. This process includes the selection of raw yarns and cottons, conceptual designing, and the setting of knitting structure and conditions.

02.Preparation

About 15,000 yarns are used at once in the process before fabric production. Our raschel machine requires winding the raw yarn on huge bobbins called beams. There are about 24 beams, and the raw yarn alone weighs almost 2 tons in total.

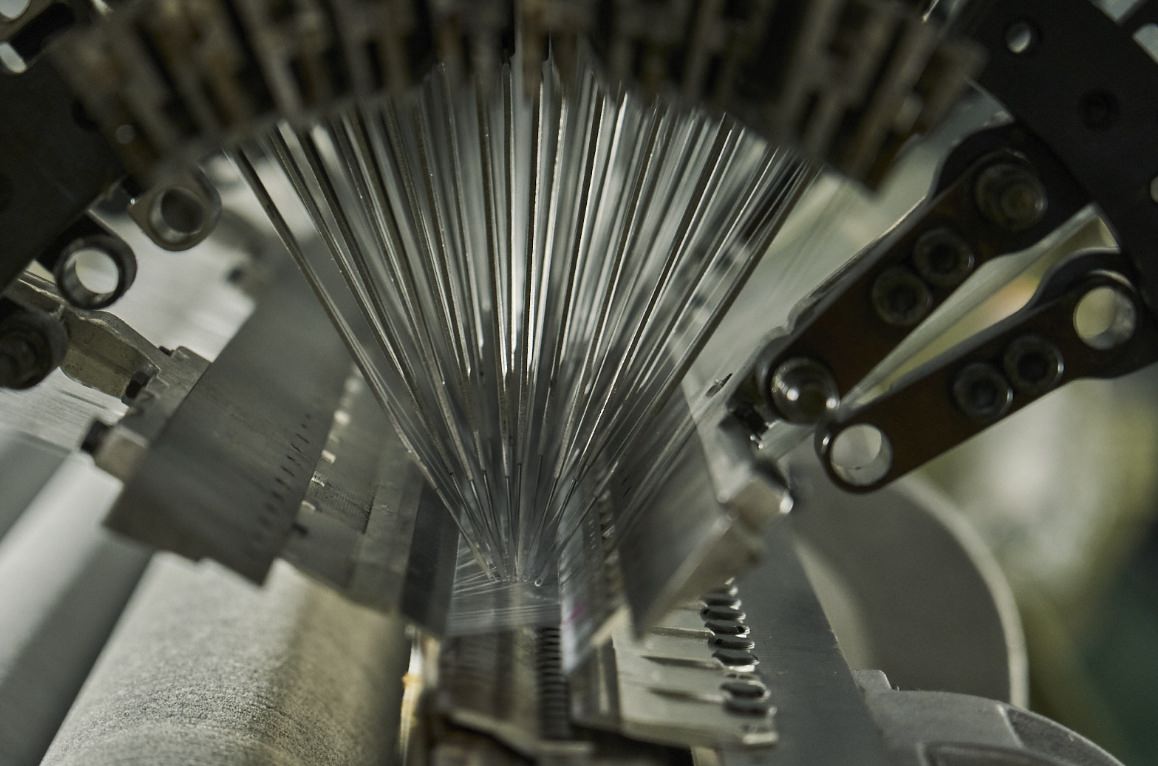

03.Knitting

The 2-ton beams attached in the preparatory process would be installed on a knitting machine. Nearly 15,000 delicate raw yarns are knitted together. Violetta owns numerous models and machines, including piezo Jacquard machines and other computerized knitting machines.

04.Dyeing

The knitted fabrics are sent to our eco-oriented and Oeko-Tex certified partner dyeing factories for dyeing and other final processing based on the apparel plan. We can see the completed high quality fabric with special features after this process.

The dyeing and finishing process is Oeko-Tex® Standard 100 certified.

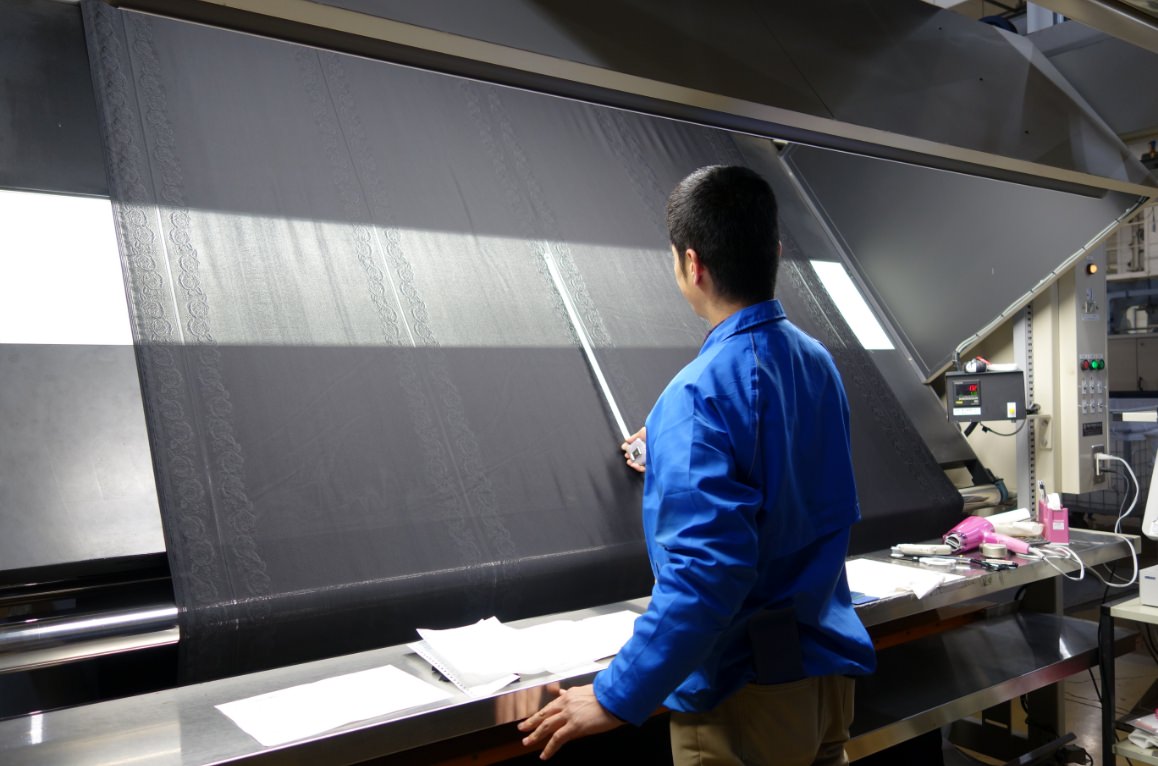

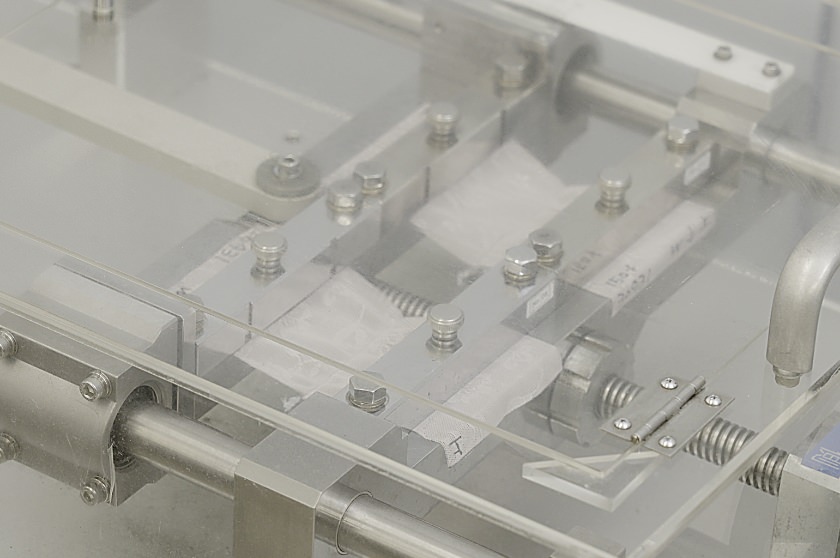

05.Quality Inspection/ Performance Testing

Final inspection and testing of the quality and functions required by apparel users. In order to provide fabrics with stable quality, we conduct color checks, appearance inspections, and fastness tests at our dyeing factories, as well as physical property tests in our own product testing laboratory. Here we introduce some of the main testing instruments among a number of testing devices.

06.Shipping

Design No. JT1224

Design No. JT1224